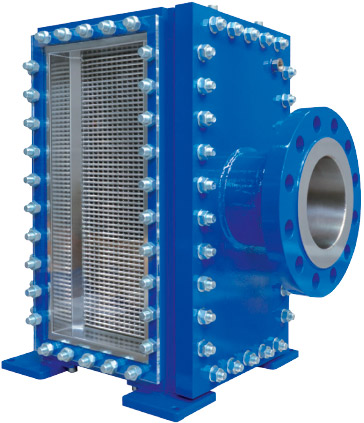

Main technical characteristics

| Operating temperature | -40 °C - 350 °C |

| Working pressure | -0,1 MPa - 4,0 MPa |

| Max.surface | 900 m2 |

Request

Simple

Extended

Information

Download

Reference list of supplies of heat exchange equipment for the period 2009-2019

Download

Reference list of supplies of heat exchange equipment for the period 2009-2019

Presentations and brochures

Documents

DECLARATIONS AND CERTIFICATES OF TR TS 010 AND 032

at the request

at the request

CERTIFICATES NAKS

at the request

at the request

LICENSES FOR DESIGN, MANUFACTURING

at the request

at the request

CERTIFICATES GOST / ISO / OHSAS

at the request

at the request

On-line viewing

On-line viewing