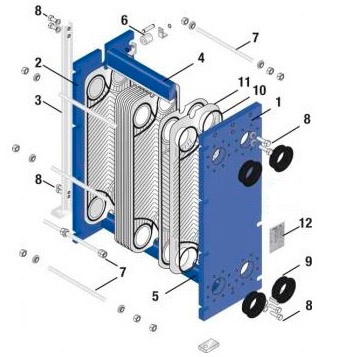

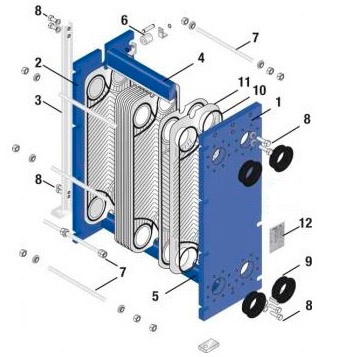

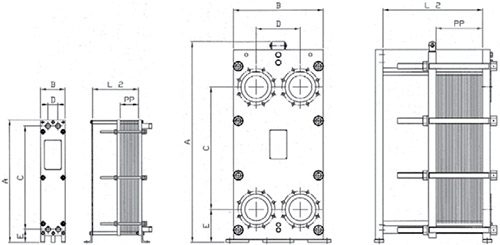

Structure of ESKM gasketed PHE and principle of operation

Structure of gasketed PHE includes thepackageof plates (with sealing gasket) placed between thebase and pressing panels, forming this structurewith two cavities, separated between each other by

plates.

The package of grooved plates with passage hole– is the core of PHE. Plates rotate with respect toeach other at an angle 180°. Thereby, there is aformation of channels through which mediums flow.

The gasket which ensures the reliable leak-proofnessof channels of medium flow,participating inheat transfer, is attached to each plate.

To achieve maximum heat transfer, warming upand heating mediums flow in the apparatus, as arule, in a counterflow on a single-pass or multi-passschemes. Pipelines connections are laid on the mainpanel, in case of multi-pass versions – on main and

pressing panels.

Structure of heat exchangers – is complete gasketed,without disconnection of pipelines of externalcommunications. There are a minimum numberof places, which contribute to deposition andaccumulation of contaminants as well as corrosionproducts and provide the possibility of mechanical

purification of all elements. At that, sealing gasketsare suitable for repeated use during disassemblyand assembly of heat exchanger.

|

- Fixed plate

- Movable plate

- Support column

- Carrying bar

- Lower plate guiding bar

- Carrier roller

- Tightening bolt and nuts

- Fixing bolts

- Rubber/metal liners

- Gaskets

- Heat transfer plates

- Name plate

|

|

Download

Reference list of supplies of heat exchange equipment for the period 2009-2019

Download

Reference list of supplies of heat exchange equipment for the period 2009-2019

at the request

at the request

at the request

at the request

at the request

at the request

at the request

at the request

On-line viewing

On-line viewing